Various Fabrication techniques

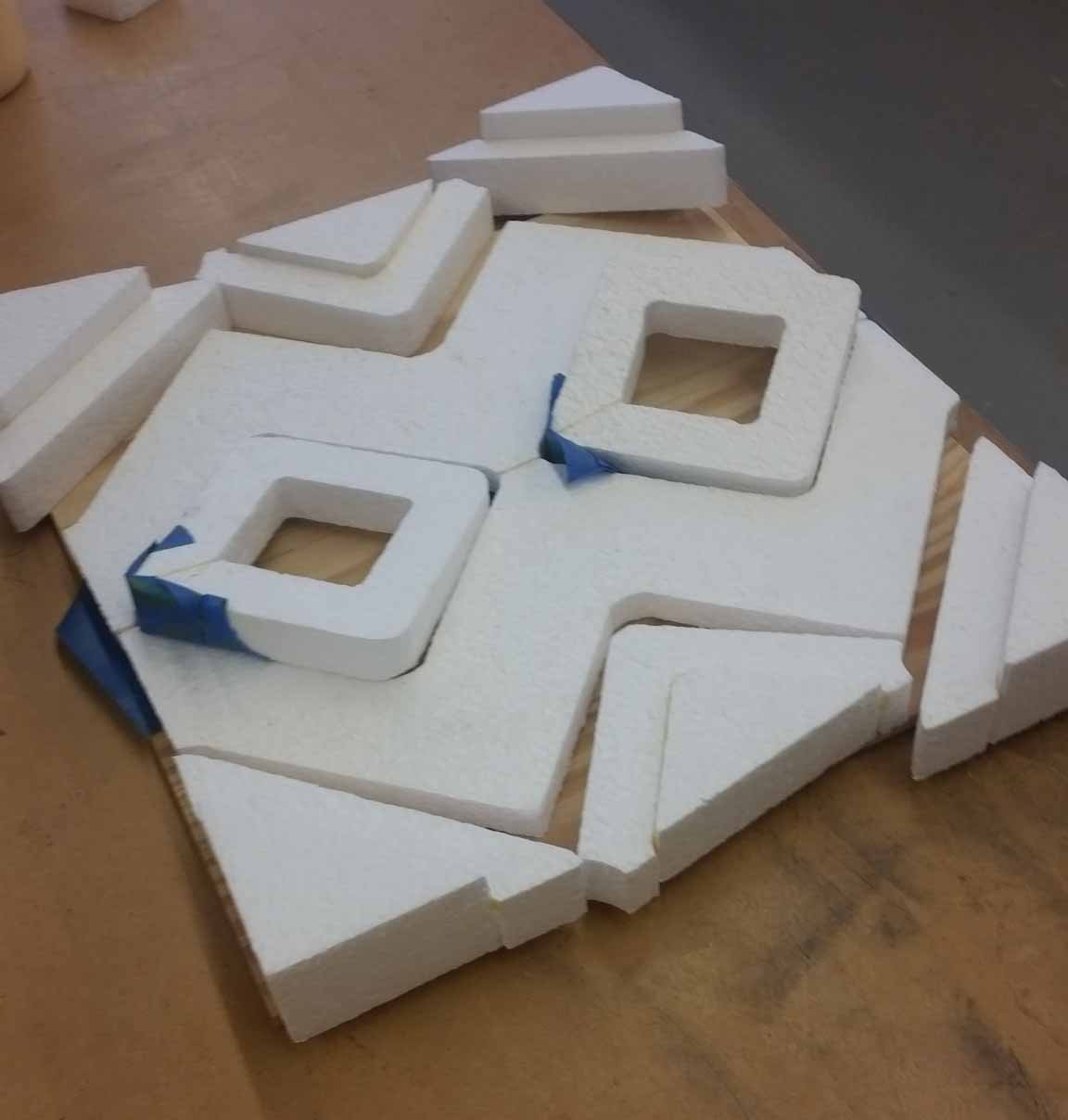

Pieces of foam were cut by the hot-wire cutter.

These pieces were put together in a box made of CNC-cut MDF. Multiple layers of glue and then oil were added to prepare this mold for the next step.

Afterwards, we poured the concrete into this mold.

And the final tile was taken out after the concrete was dry.

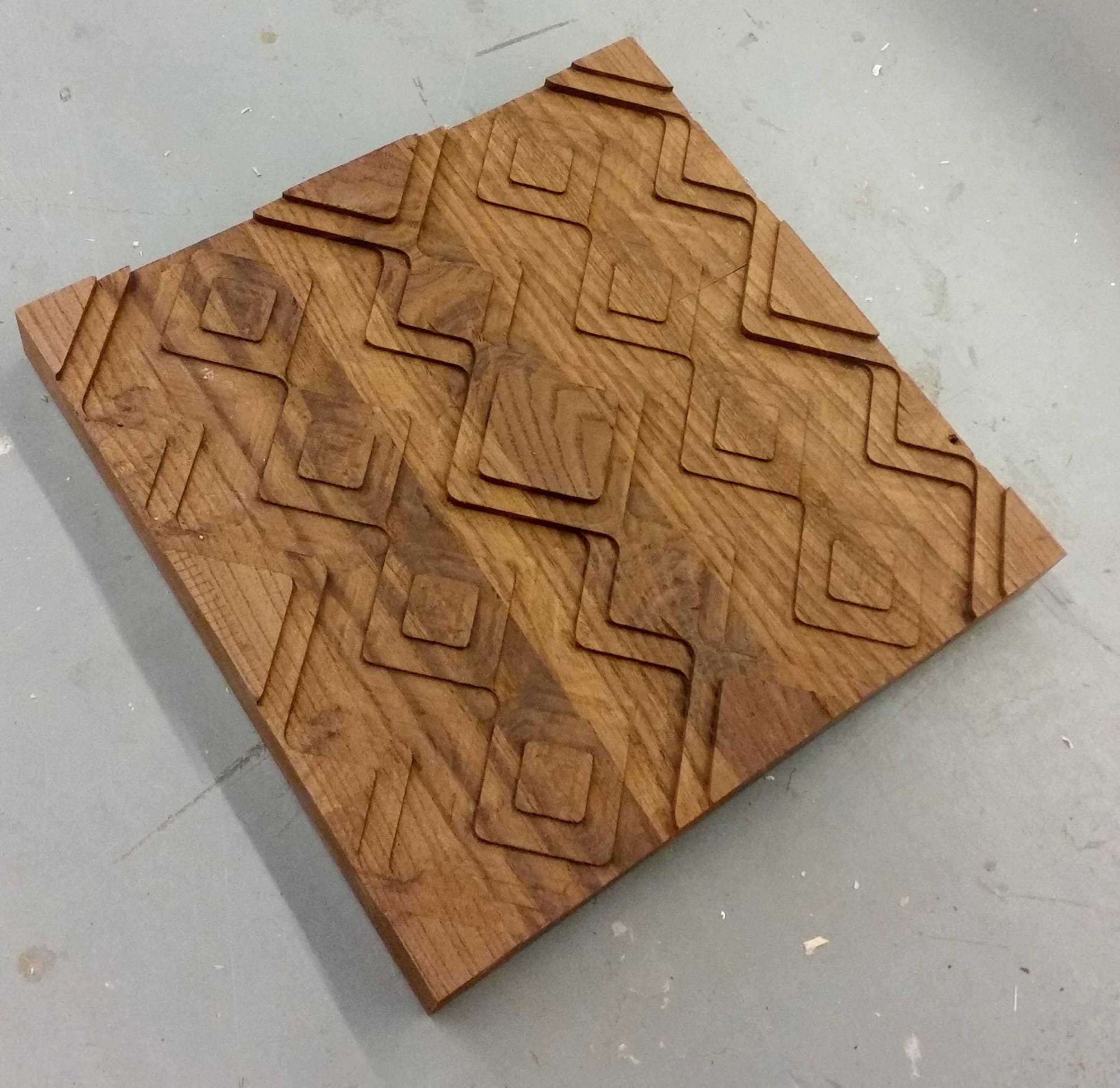

The next tile was made of pieces of wood that were glued together and cut to size. The glued together piece was later cut by the CNC machine to make this tile.

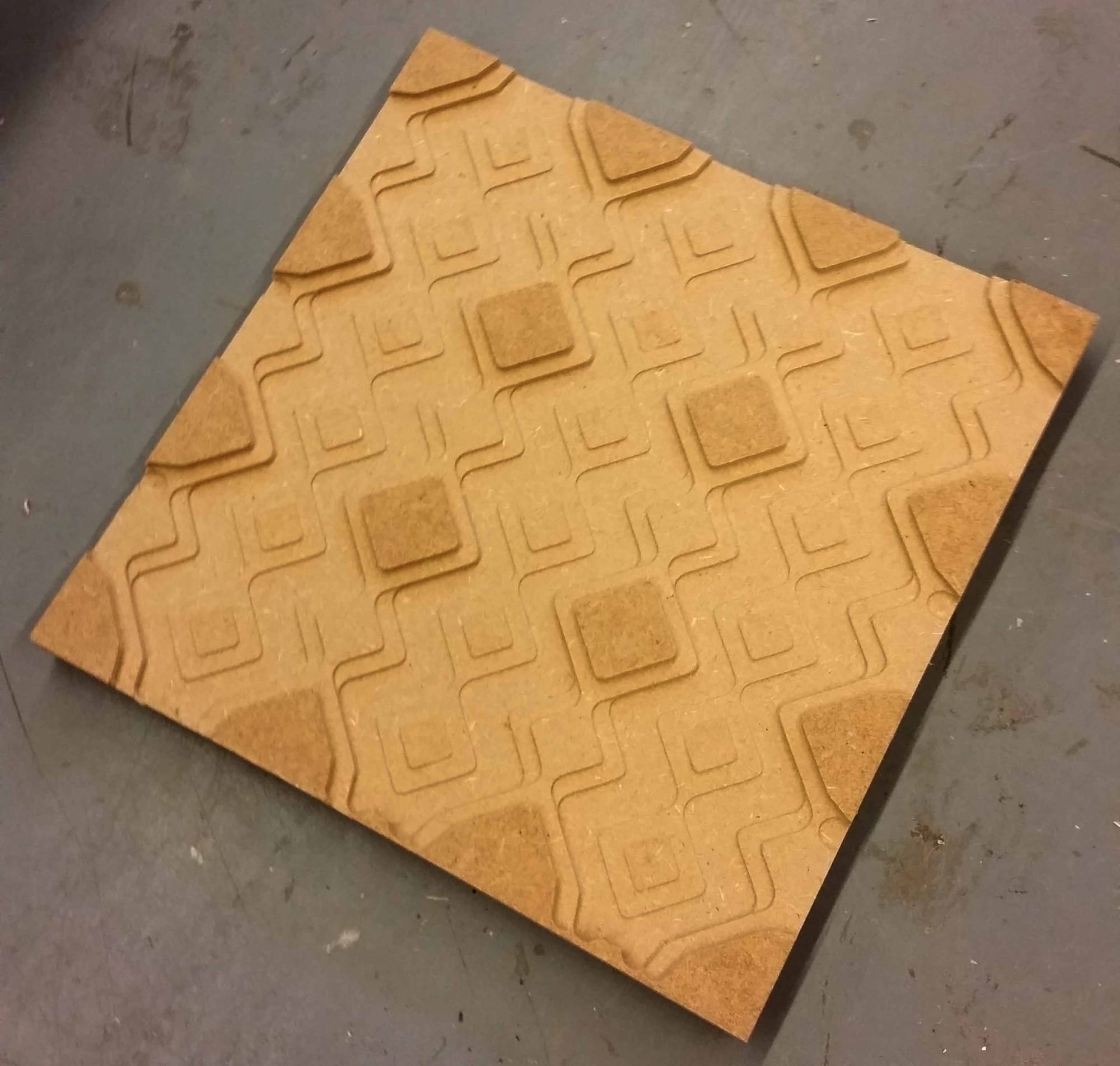

The mold for the plastic tile was made by cutting a mdf material by the CNC machine.

A layer of plastic was then shaped on top of this mold, using the thermoforming technique.

The plastic was then cut to make the final tile.

Finally, The 3 tiles were assembled on top of a wooden column, held by metal brackets that were cut by the waterjet machine. These brackets were assembled by rivets and welding techniques.